COMMUNITY

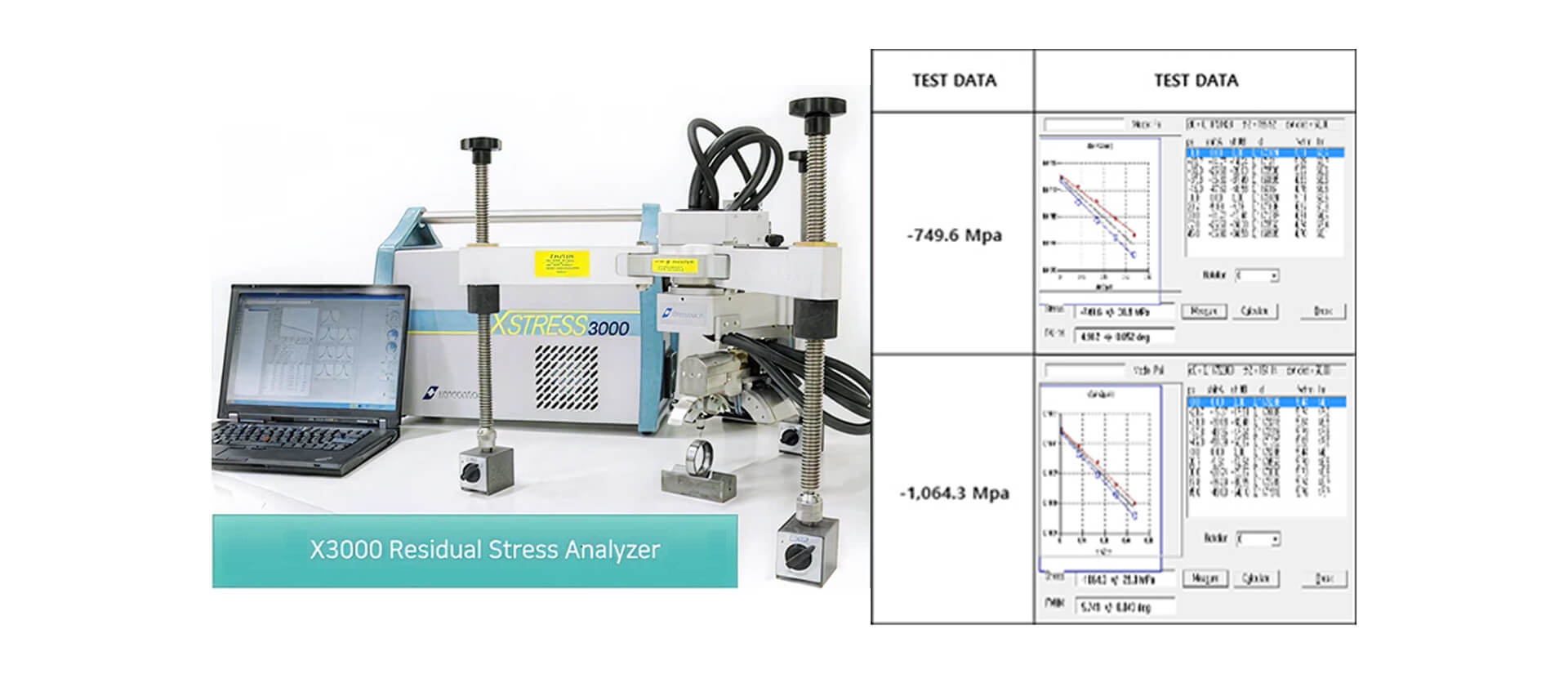

Even without external force, stress can remain inside a material, which is called residual stress. It occurs during manufacturing processes such as heat treatment, machining, and welding, and affects material strength and dimensional accuracy. In particular, tensile residual stress tends to reduce strength, while compressive residual stress increases strength. Gears and shaft components improve fatigue strength by hardening the surface and inducing compressive residual stress through shot peening.

Product information (drawing/image), detailed measurement location, number of measurements, required schedule, method and date of specimen delivery, contact information

Daedong Gear Co., Ltd. CEO: Seoh Jong-hwan Business Registration No. : 619-81-3305

Address : 42, Gongdan 1-ro, Sanam-myeon, Sacheon-si, Gyeongnam 52528, Republic of Korea Tel: +82-55-851-2300 E-Mail : d21200@deadong.co.kr

Copyright © 2025 deadonggear. All Rights Reserved.

We value our customers’ information and comply with the Personal Information Protection Act. Collected personal data is used only to provide the best possible service and is collected to the minimum extent necessary.

Purpose and Items of Personal Data Collection

Purpose of collection: Event notifications and marketing purposes

Collected items: Name, contact information, email address, address, etc.

Collection method: Via the company website and other channels

Processing and retention period: Data will be destroyed without delay within 5 years after the processing purpose is fulfilled.

Withdrawal of consent for collection/use: You may withdraw consent to the use of your information. Withdrawal may result in loss of access to event information. Information regarding personal data handling and outsourcing is provided.

※ Notice regarding refusal of consent: You may refuse collection/use of personal data, but this may limit your use of the website.